01

Yarn inspection

Testing the quality of cotton yarn

02

Yarn Entered the Warehouse

Safeguard the cotton yarn used in the production of towels

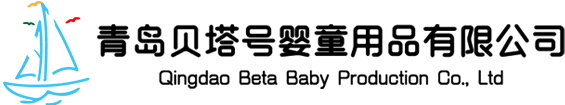

03

The Whole Epoch

Roll 1 / 2 of the yarns that make up the towel onto the axis

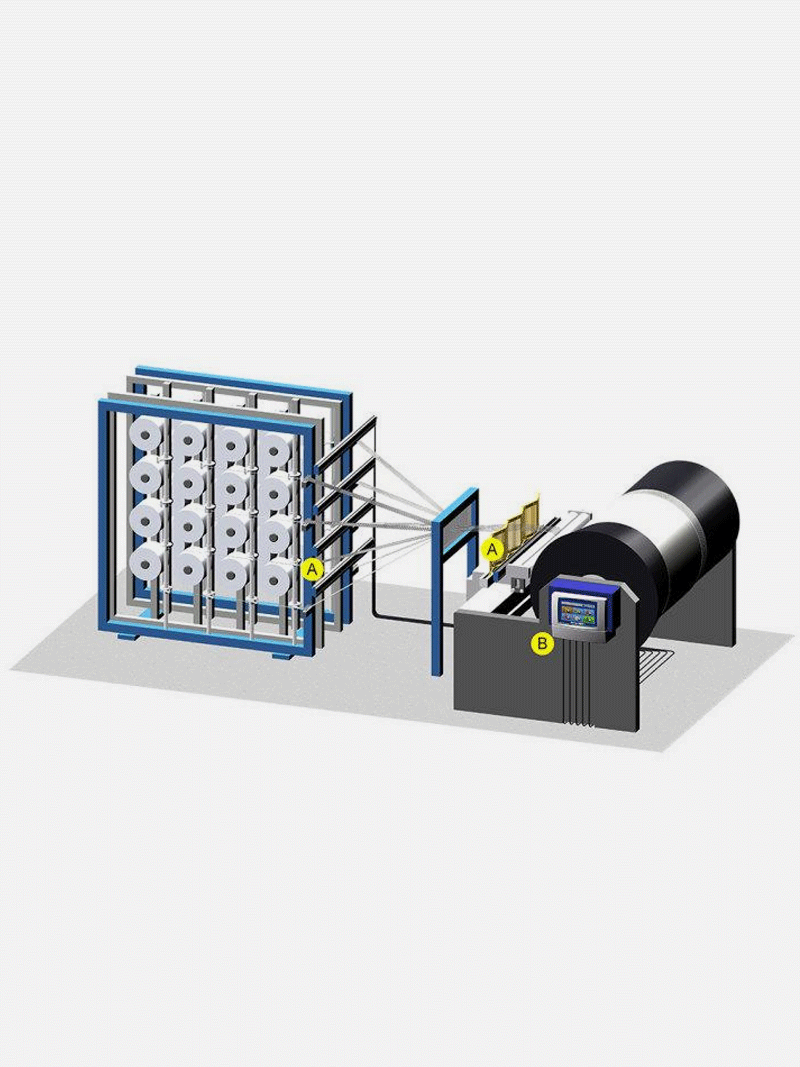

04

Dye Yarn

Plasma processing of cotton yarn

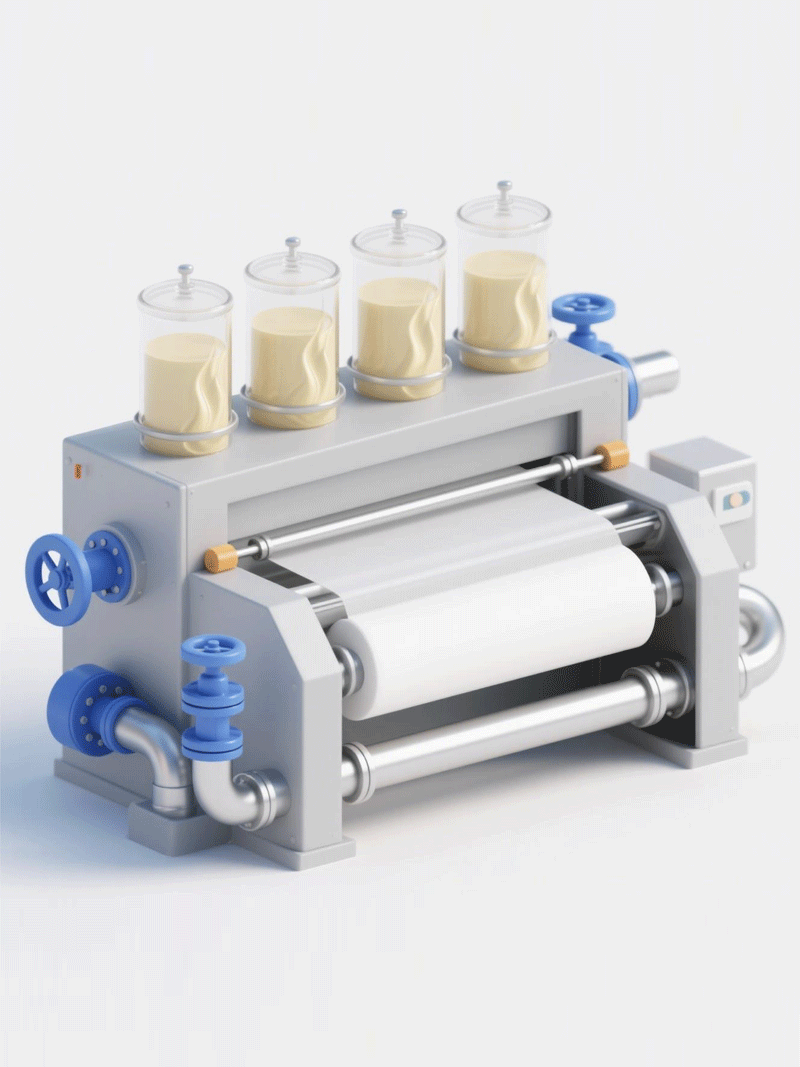

05

Get on Machine

Attach the yarn one by one to the machine and put it back together

06

Weave

Put the rolled cotton yarn on the shaft of the weaver and start tow the towels

07

Drain Testing

Make sure the fabric that has been woven is free of defects

08

Bleach Dyeing

After removal of impurities from the fabric, dyeing

09

Drying

Dry the fabric

10

Scaling Style

Prepare and shape the fabric according to the needs of the product

11

Corrupt Practices

Vertical cutting of fabric

12

Prints

Patterned on fabric

13

Embroidery

Add embroidery to the fabric

14

Sewing

Sew the vertical and cross side of a towel

15

Item 1 Inspection

Accept the product according to the standard (including dirty, foreign contents, different contents, etc.)

16

First Needle Test

After passing the product through the syringe machine, place it in a transit warehouse for storage

17

Second Needle Test

Remove the product from the transit warehouse, 2 screening before

18

Packaging

Fold, wrap, apply stickers and other processes to the product to finally complete the product packaging

19

Containers

Include it in a packing carton

20

Shipments

loaded into the container and transported to the port